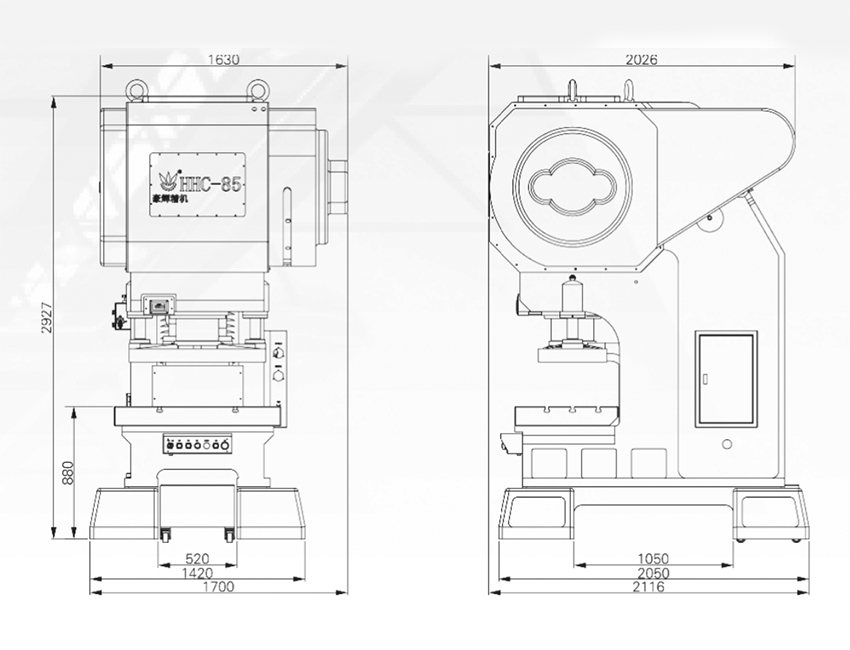

HHC-85T Peb Txoj Kev Qhia Sab Sauv Tsis Siv Neeg Punch Xovxwm Tshuab

Cov Kev Ntsuas Tseem Ceeb:

| Qauv | HC-85T | |||

| Peev Xwm | KN | 850 | ||

| Qhov ntev ntawm txoj hlab ntsha | MM | 30 | 40 | 50 |

| Qhov siab tshaj plaws ntawm SPM | SPM | 600 | 550 | 500 |

| SPM tsawg kawg nkaus | SPM | 200 | 200 | 200 |

| Qhov siab tuag | MM | 315-365 | 310-360 | 305-355 |

| Kev hloov qhov siab ntawm lub pwm | MM | 50 | ||

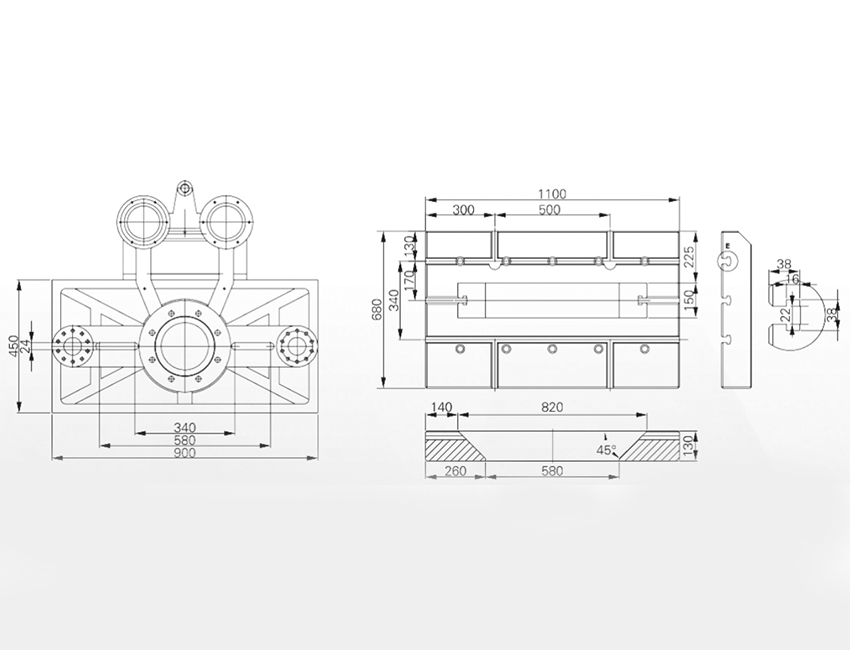

| Thaj chaw swb | MM | 900x450 | ||

| Thaj chaw txhawb nqa | MM | 1100x680x130 | ||

| Qhov qhib ntawm lub qhov (bolster opening) | MM | 150x820 | ||

| Lub cev muaj zog tseem ceeb | KW | 18.5kwx4P | ||

| Kev raug |

| JIS/JIS Qib Tshwj Xeeb | ||

| Tag Nrho Qhov Hnyav | TON | 14 | ||

Cov yam ntxwv tseem ceeb:

1. Lub txaj yog ua los ntawm cov hlau cam khwb cia muaj zog nrog kev ntxhov siab sab hauv, uas ua rau cov khoom ruaj khov thiab raug hloov pauv thiab tsim nyog tshaj plaws rau kev tsim khoom txuas ntxiv mus.

2. Cov ncej qhia ruaj khov ntawm ob sab ntawm lub slider raug ntxiv rau cov qauv slider ib txwm muaj los ua kom lub slider muaj kev tiv thaiv zoo dua rau kev thauj khoom deflection thiab txo qhov hnav ntawm ib sab, uas yog qhov tsim nyog rau kev siv cov tuag loj hauv cov txheej txheem ntev.

3. Qhov kev hloov kho tuag yog nruab nrog qhov siab tuag thiab lub cuab yeej hydraulic xauv, uas yooj yim rau kev ua haujlwm hloov kho tuag.

4. Kev tswj hwm microcomputer ntawm tib neeg thiab tshuab, tus nqi, qhov system saib xyuas qhov yuam kev rau kev ua haujlwm yooj yim.

5. Txais yuav qhov siab ntawm lub cev muaj zog, nrog rau qhov qhia qhov siab ntawm lub cev muaj zog, yooj yim kho qhov siab ntawm lub cev muaj zog.

Qhov Loj:

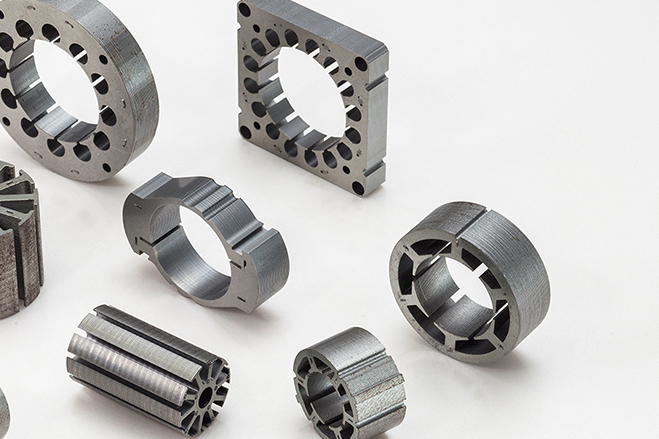

Cov Khoom Siv Xovxwm:

Lub Tshuab Fais Fab Xovxwm Tsav Lub Flywheel Los Ntawm Lub Cev Muaj Zog, Tsav Lub Crankshaft Txuas Qws Los Ntawm Clutch Thiab Lub iav Kis Mus Rau Sab Sauv Thiab Sab Hauv, Thiab Tsav Lub Pwm Tensile Los Ua Lub Phaj Hlau. Thiab Lub Tshuab Fais Fab Xovxwm Muaj Ob Lub Slider, Muab Faib Ua Lub Thaiv Sab Hauv Thiab Sab Nraud Lub Slider, Hauv Lub Slider Tsav Lub Pwm Punch Los Yog Tuag, Sab Nraud Lub Siab Ntawm Lub Slider Los Tsav Lub Pwm Mus Rau Lub Kauj Vab, Lub Ntug Siab Ua Ntej Thaum Lub Ntug Hlau Tensile, Lub Thaiv Sab Hauv Ua Lub Luag Haujlwm Ncab Dua.

Cov Lus Nug Feem Ntau

- Lo lus nug: Howfit puas yog Lub Tshuab Xovxwm Chaw Tsim Khoom lossis Lub Tuam Txhab Lag Luam Tshuab? Lus teb: Howfit Science thiab Technology CO., LTD. yog lub chaw tsim khoom Tshuab Xovxwm uas tshwj xeeb hauv Kev Tsim Khoom thiab Muag Khoom ntawm Fan lamination high speed xovxwm nrog thaj chaw ua haujlwm ntawm 15,000 m² rau 16 xyoo. Peb kuj muab kev pabcuam hloov kho Fan lamination high speed xovxwm kom txaus siab rau koj cov kev xav tau tshwj xeeb.Lo lus nug: Puas yooj yim mus xyuas koj lub tuam txhab?Teb: Yog, Howfit nyob hauv nroog Dongguan, xeev Guangdong, Sab Qab Teb ntawm Tuam Tshoj, qhov chaw nyob ze ntawm txoj kev loj, cov kab metro, chaw thauj mus los, txuas mus rau hauv nroog thiab suburbia, tshav dav hlau, chaw nres tsheb ciav hlau thiab yooj yim mus xyuas.

Lo lus nug: Koj tau ua tiav daim ntawv cog lus nrog pes tsawg lub tebchaws?

Lus Teb: Howfit tau ua tiav daim ntawv cog lus nrog Lavxias Federation, Bangladesh, Republic of India, Socialist Republic of Vietnam, United Mexican States, The Republic of Turkey, Islamic Republic of Iran, Islamic Republic of Pakistan thiab lwm yam rau tam sim no.

Lus Nug: Lub Tonnage Ntau Yam Ntawm Howfit High Speed Press Yog Dab Tsi?

Lus Teb: Howfit tau tsim cov kiv cua lamination siab ceev xovxwm uas npog qhov muaj peev xwm ntawm 16 txog 630 Tonnage. Peb muaj pab pawg kws tshaj lij rau kev tshawb fawb thiab kev txhim kho hauv kev tsim khoom, kev tsim khoom thiab kev pabcuam tom qab.

Kev Xa Khoom Thiab Kev Pabcuam:

1. Cov Chaw Pabcuam Neeg Siv Khoom Thoob Ntiaj Teb:

① Tuam Tshoj: Lub nroog Dongguan thiab Foshan ntawm Guangdong xeev, Changzhou nroog ntawm Jiangsu xeev, Qingdao nroog ntawm Shandong xeev, Wenzhou nroog thiab Yuyao nroog ntawm Zhejiang xeev, Tianjin Municipality, Chongqing Municipality.

② Is Nrias teb: Delhi, Faridabad, Mumbai, Bengaluru

③ Bangladesh: Dhaka

④ Lub Tebchaws Turkey: Istanbul

⑤ Islamic Republic of Pakistan: Islamabad

⑥ Lub Tebchaws Nyab Laj Socialist: Ho Chi Minh City

⑦ Lavxias teb sab Federation: Moscow

2. Peb muab kev pabcuam hauv tsev kawm ntawv hauv kev sim ua haujlwm thiab kev cob qhia ua haujlwm los ntawm kev xa cov engineers.

3. Peb muab kev hloov pauv dawb rau cov khoom siv tshuab uas tsis ua haujlwm thaum lub sijhawm lav.

4. Peb lav tias qhov kev daws teeb meem yuav muab rau hauv 12 teev yog tias muaj teeb meem tshwm sim rau peb lub tshuab.

Qhov txawv ntawm Fan lamination high speed press Machine thiab ordinary Press Machine yog dab tsi? Hauv ntau lub lag luam kho tshuab, Press yog ib qho cuab yeej tseem ceeb rau kev tsim pwm / lamination. Muaj ntau hom thiab cov qauv ntawm cov presses. Yog li ntawd, qhov txawv ntawm High Speed Presses thiab ordinary presses yog dab tsi? Puas yog qhov ceev sib txawv ntawm ob qho no? Fan Lamination High Speed Press puas zoo dua li qub? Qhov txawv ntawm high speed press thiab ordinary punch yog dab tsi? Qhov txawv ntawm High-speed Press yog nws qhov tseeb, lub zog, ceev, kev ruaj khov ntawm lub cev & kev ua haujlwm tsim kho. Fan lamination high speed press yog qhov tshwj xeeb dua thiab tus qauv siab dua li cov punch ib txwm, thiab cov kev xav tau siab. Tab sis tsis yog Fan Lamination High Speed Press dua li lub tshuab xuas nrig ib txwm. Thaum lub sijhawm yuav khoom, nws kuj nyob ntawm daim ntawv thov, yog tias qhov ceev stamping yog qis dua 200 strock ib feeb, ces koj yuav xaiv lub tshuab xuas nrig ib txwm lossis pheej yig dua. Nov yog qhov sib txawv tseem ceeb ntawm Fan lamination Fan Lamination High Speed Press thiab ordinary punch.

- Yuav ua li cas txog cov nqi xa khoom?

Tus nqi xa khoom nyob ntawm seb koj xaiv txoj kev twg kom tau txais cov khoom. Feem ntau, kev xa khoom sai yog txoj kev ceev tshaj plaws tab sis kuj kim tshaj plaws. Kev xa khoom los ntawm hiav txwv yog qhov kev daws teeb meem zoo tshaj plaws rau cov khoom loj. Cov nqi thauj khoom peb tsuas yog muab tau rau koj yog tias peb paub cov ntsiab lus ntawm qhov ntau npaum li cas, qhov hnyav thiab txoj kev. Thov hu rau peb kom paub ntxiv.

Koj puas lav tias cov khoom xa tuaj zoo thiab ruaj ntseg?Yog, peb ib txwm siv cov ntim khoom zoo rau kev xa tawm. Peb kuj siv cov ntim khoom tshwj xeeb rau cov khoom txaus ntshai thiab cov neeg xa khoom txias uas tau lees paub rau cov khoom rhiab heev rau qhov kub thiab txias. Cov ntim khoom tshwj xeeb thiab cov kev cai ntim khoom tsis yog tus qauv yuav raug nqi ntxiv.

Cov Khoom Zoo

- Kev nias ceev ceev rau EI lamination yog qhov tsim nyog rau EI daim ntawv stamping. EI precision punch yog ib lub cuab yeej muaj zog rau kev tsim khoom loj ntawm EI. Tsuav yog lub chaw tsim khoom phim cov pwm ua ntej, nws tuaj yeem stamp tawm tas li ntawm qhov precision punch. Nws muaj qhov zoo ntawm kev ceev ceev, kev raug siab, kev lag luam zoo thiab kev siv dav.

Kev nias ceev ceev rau EI lamination tuaj yeem nruab nrog cov khoom noj tsis siv neeg ntawm ntau qib thiab cov lus qhia rau kev tsim khoom tsis siv neeg. Los ntawm kev sib xyaw cov khoom tsim nyog, nws yooj yim kom paub txog hom kev tsim khoom ntawm ib tus neeg tswj ntau lub tshuab.

Lub tshuab qauv muaj cov hlau casting siab rigidity, uas lav qhov ruaj khov, qhov tseeb thiab kev siv mus sij hawm ntev. Nrog rau kev yuam kom lubrication, qhov thermal deformation yuav raug txo qis. Lub ncej ob chav thiab ib lub plunger guide tau ua los ntawm tooj dag thiab nws txo qhov kev sib txhuam kom tsawg kawg nkaus. Sib npaug qhov hnyav rau kev xaiv los txo qhov kev co. HMI yog tswj los ntawm microcomputer. Nrog rau lub computer maub los siab heev, Howfit Presses siv cov software tsim tshwj xeeb stamping. Lub computer muaj zog ua haujlwm thiab muaj peev xwm nco loj. Nrog rau qhov chaw teeb tsa parameter, nws muaj lub luag haujlwm ntawm kev qhia qhov txhaum thiab ua rau kev ua haujlwm yooj yim dua.

Kev Teeb Tsa Xaiv Tau

- 1. Lub Tshuab Pub Khoom Noj (Xaiv Qhov Dav: 105/138 hli)

2. Gripper Feeder (Ib Leeg / Ob Chav)

3. Iav Feeder (Xaiv Dav: 150/200/300/400)

4. Phaj Fais Fab (500kg Dais Tau)

5. Ob Chav Taub Hau Khoom Siv Txais

6. Hauv qab qhov chaw tuag saib xyuas Ib qho taw tes

7. Lub chaw tuag hauv qab saib xyuas Ob Chav Point

9. Kev Ua Haujlwm Kho Qhov Siab Hluav Taws Xob

10. Teeb Ua Haujlwm